Walnut Shells Abrasive

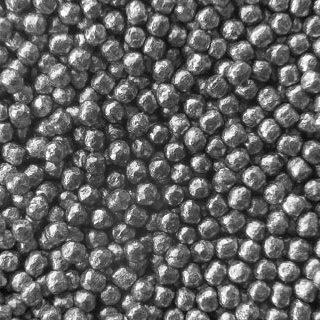

If you’ve never heard of the process of walnut shell sandblasting, it is a very effective way of removing rust and corrosion from an object without disturbing the layers underneath. Walnut shells have some very special qualities which enable them to be used as an effective medium for blasting away unwanted material from any surface, while leaving the layers below intact and unharmed.

What is walnut shell blasting?

- Walnut shell blasting is a process which is frequently used to remove rust.

- It is effective because crushed walnut shells are definitely hard enough to dislodge the rust, but are also soft enough that they will not damage the surface being blasted.

- Since crushed walnut shells do not absorb any moisture, it would be possible to use and re-use your mixture of walnut shells many times before having to replace the mixture.

- This mixture can also be used for finishing operations as well as de-flashing and de-burring, so as to remove unwanted pieces of material on any product.

Can you use walnut shells in a sandblaster?

Walnut shells are ideal for use in a sandblaster. The process of sandblasting involves the use of an abrasive material such as walnut shells, to strip off the uppermost layer of some object like a boat, a vehicle, or anything else which has multiple layers of protective coating. Walnut shell sandblasting abrasive does little to no harm whatsoever to the primer coat underneath, or to any other coating which has been applied to an object.

Before the discovery of walnut shell blast media, any object which needed rust or corrosion removed, had to be stripped right down to bare metal. This of course, was a more time-consuming and costly process, and it often did at least some damage to the metal underneath. Now with the usage of walnut shells for sandblasting, a much gentler process is possible, and only the top layer of any protective coating is affected.

What are crushed walnut shells used for?

Walnut shells as one of the most effective blasting abrasives, they have a number of other applications which make them extremely useful. One application, walnut shell blasting is great for paint removal from sheet metal, cleaning engines and transmissions. They are also used in mixtures to prevent slipping, such as on decks, stairs, ramps, floors, and pools.

These shells are environmentally safe in that they are non-toxic and biodegradable; they require no flammable solvents; they are a natural and dust free product; they do not cause Silicosis, which can occur from some sand and silica products; and they’re used by many government agencies.

Our Abrasives

We specialize in a wide variety of blasting abrasives for cleaning, finishing and surface preparation. aluminum oxide, steel shot and steel grit, glass bead, starblast and more are available in large quantities by contacting our sales team. If you need help choosing the right abrasive, fill out the form at the bottom of the page or contact us here.

Sandblasting is what N.T. Ruddock is all about. Besides being one of the most knowledgeable sources in the industry we consider ourselves one of the top sand blasting pro/expert s in the industry. We are the source for abrasives, OSHA safety equipment, sandblast pots and all the products you need to do metal finishing, powder coatings and surface preparation to Mil spec. Brands we stock are Clemco Industries, Schmidt Abrasive Blasting Equipment, Western Technology, Empire Abrasive Equipment, Kennametal, Blast-It-All and Bullard products.

N.T. Ruddock carries all the abrasives like garnet, aluminum oxide, glass bead and recycled glass. These products are really popular for preparing steel and concrete for finishing. It is important that you prepare the surface for coatings to fight corrosion.