5 Best Sand Blasting Sand

When you need sand blasting sand or other blasting media, there is a wide range of materials to choose from for your abrasive blasting project. In order to select the best media for your needs, it is important to understand your options and their uses in sand blasting. N.T. Ruddock offers many blasting materials. We have several blasting sand options from extra fine to coarse. Shipping is available for all your abrasive blasting media.

Glass Bead – Blasting Media

Glass beads are a good option for sandblasting media because they are smooth and round, which provides a good finish. They have many uses, such as:

- Deburring

- Cleaning

- Peening

- Finishing

- Brightening

- Preparing surfaces for coating

- Removing cosmetic flaws

There are a large number of materials that glass beads are used on, including stainless steel, bronze, plastic and rubber, among others. This makes glass beads a flexible option for sand blasting sand. In addition, they are less abrasive than other materials, leaving a smooth surface and no embedded residue. Glass beads have high levels of recyclability and are environmentally safe to use. They can be used on pipe fittings, castings, structural steel and other types of parts.

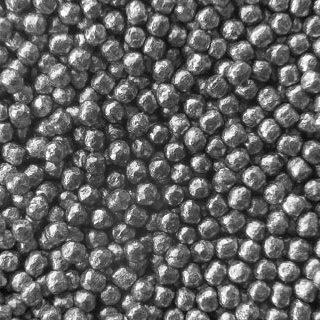

Steel Shot – Blasting Media

Steel shot is frequently used for improving, stripping and cleaning metal surfaces. The type of steel shot, including its size, determines the finish on the part after sandblasting sand application. When smaller steel shot is used, the application leaves a smoother surface. A larger steel shot leaves a rougher surface after application. Most often, steel shot is used for:

- Cleaning

- Polishing

- Preparing surfaces for coating

- Shot peening

Steel shot is durable for use as sand blasting sand because it is made from steel. In addition, its durability means it can be recycled many times. Its spherical shape prepares parts for coatings with very low dusting. Steel shot can be used in both wheel blasting and pneumatic (air) blasting.

Baking Soda (Bi-carb) – Abrasive

Baking soda, also known as sodium bicarbonate, is a popular choice for air blasting when the surface must be kept scratch-free and when containment removal is necessary. Though there are many benefits for using sodium bicarbonate as a sand blasting sand, there are things to take into consideration, as well. Baking soda is a one-time-use media; it cannot be recycled. In addition, since it absorbs moisture, the air must be clean and dry when blasting with baking soda. Baking soda is effective for:

- Fire damage and restoration

- Mold removal and remediation

- Mold and die cleaning

- Paint, coat and graffiti removal

One advantage of using sodium bicarbonate as a sand blasting sand is that it can be used with parts that have a film of grease, oil or moisture on them.

White Aluminum Oxide (ALOX) – Abrasive

White aluminum oxide is a very pure sand blasting sand. This is why it is frequently used for high-performance microdermabrasion sandblasting equipment. Aluminum oxide can be recycled many times in blasting and is more cost-effective than many alternatives. This is why it is more widely used as a sandblasting media. It is also safer than sand and its consistent size provides a smoother finish after application. In addition, its hardness compared to other materials makes it attractive because it cuts deeper and more effectively. This abrasive is effective for:

- Turbine blades

- Valves

- Pistons

- Engine heads

White aluminum oxide is frequently used in the automotive and airline manufacturing industries. It is effective for preparing a surface for coating, such as for paint.

Garnet – Blasting Media

Garnet is a more abrasive blasting media that can be used as a sand blasting sand. It is environmentally-friendly, especially in comparison to many other blasting medias. Garnet is available in many sizes and shapes. It can either be tumbled, which produces a smooth media, or left rough. This impacts the smoothness of the part after sand blasting sand application. Garnet is a low-dust media and safe to use near water. It can be used with fiberglass, dry docks, and many other materials and situations. Garnet is effective for:

- Preparing for industrial coating

- Cleaning

- Finishing

- Polishing

Garnet is a good media to reduce the time spent blasting because it cuts more precisely and deeper than other sand blasting sand options.

No matter what type of sand blasting sand you are seeking, N.T. Ruddock offers a variety of blasting sand options that will meet your abrasive blasting needs. If you have questions about what blasting media is best for your sand blasting needs, contact us today and we can help ensure that your sand blasting sand (or glass) will be the best choice for your blasting project.