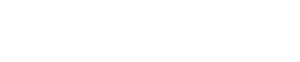

Convert your BNP 220 suction blast cabinet into a safe, efficient automated blast system – complete with

- Indexing or continuous turntable

- Rotating or stationary satellites

- Cycle timer

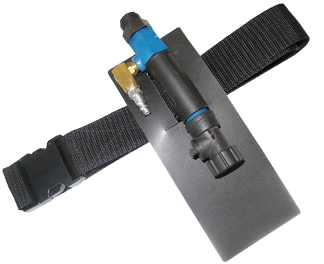

- Versatile rack for up to five blast guns

Automatic blasting increases productivity over manual blasting. One operator loads and removes parts, while the turntable carries the parts into the blast enclosure for processing. The operator can quickly and easily adjust the variables to suit the part being blasted – changing gun positions, cycle timers, part rotation speed and turntable speed. Because the cabinet doors stay closed, automatic blasting can continue, uninterrupted, for as long as needed.

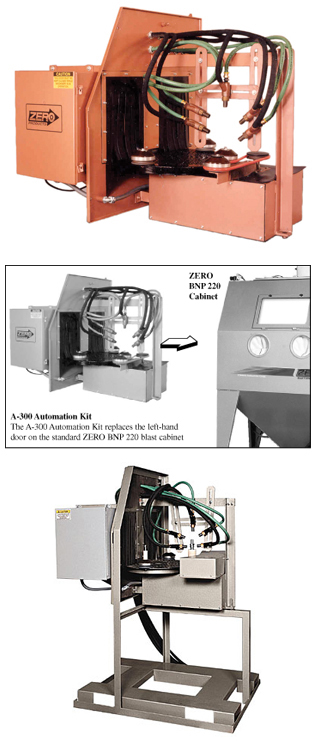

The A-300 automation kit increases the versatility of your BNP 220 blast cabinet, yet still allows manual processing. The A-300 kit – available for factory or field installation – replaces the left door of the standard cabinet.

The kit includes two variable-speed DC motors – one for the turntable, the other for satellite rotation. Each of the four satellites holds up to 25 pounds, including part and any required fixturing.

Optional satellite fixtures can be designed to fit your part or fabricate them in your shop as the need arises. The rubber-curtained vestibules allow parts/fixture combinations of up to 9 inches tall by 6 inches wide.

Applications for the A-300 include cleaning and finishing a variety of automotive parts (from engine valves to caliper cups), peening aircraft turbine blades, cleaning small electric motor cores, and etching printer rollers.

With optional special fixtures and masking, an A-300 automation kit lets you thoroughly etch handgun parts prior to plating, selectively etch logos and lettering into glass bottles, even deburr and finish plastic tool bodies.

High Production & Consistent Results

As the turntable stops at the blast station, the satellite begins rotating. Thanks to precise control of indexing, rotation speed, and blast cycle, each part receives consistent blast intensity and duration.

And with five automatic blast guns, the A-300 processes each part in a fraction of the time it takes to blast by hand. The result – cleaned parts with little wasted air or media.

To ensure consistent blast intensity, all five automatic guns get their air supply from a central air manifold, controlled by a single pilot regulator with independent gauge.

All of the guns get their media supply from a conical media manifold, which replaces the standard metering valve at the bottom of the BNP 220’s 900-cfm reclaimer. The sixth position on the media manifold connects to the standard BNP gun. Separate metering adjustments allow precise media flow to each gun.

Rubber curtains at the vestibule help keep dust and media inside, while maintaining sufficient air flow for efficient media reclaim.

Factory or Field Installation

The A-300 automation kit can be factory installed, which includes a NEMA 12 panel for the start/stop button, cycle timer, rotation controls, and turntable speed.

Field installation, available through authorized ZERO Distributors only, retains the BNP 220’s standard panel for start/stop and pressure control. The automation controls come housed in a separate NEMA 12 enclosure.

Installation takes just 4 to 5 hours, in most applications.

Reviews

There are no reviews yet.