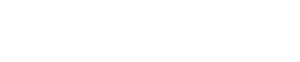

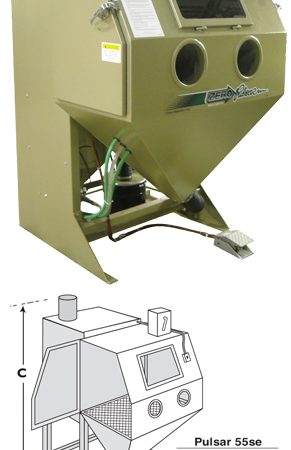

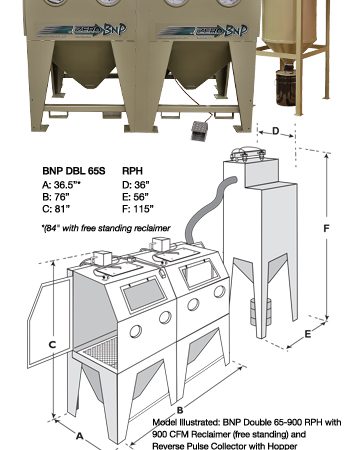

Industrial Sandblaster

An industrial sandblaster is a specialized piece of equipment used for the process of abrasive blasting. It is designed to propel abrasive materials, such as sand, grit, or other abrasive media, at high velocities to clean, strip, etch, or prepare surfaces. Industrial sandblasters are used in a wide range of applications, including surface preparation, cleaning, paint and coating removal, rust removal, and more.

Sandblasting vs. Media Blasting

You may have heard the terms “sandblasting” and “media blasting” used interchangeably, but there are some key distinctions. Both are abrasive blasting techniques, but while they serve similar purposes, there are differences in the abrasive media used, the applications, and some safety considerations.

So, what is the difference between sandblasting and media blasting? Historically, sand was the primary abrasive medium in sandblasting, hence the name. However, due to health and environmental concerns associated with the inhalation of silica dust from sand, other are often used today. Sandblasting was initially used in a wide range of applications, including cleaning, rust removal, paint stripping, and surface preparation. It’s suitable for heavy-duty applications. The use of sand as an abrasive medium can generate harmful silica dust, which poses health and environmental risks. Many regions have imposed regulations on sandblasting to mitigate these concerns. PPE is essential when sandblasting outside of a cabinet. A respirator is needed to protect against breathing silica dust, along with a helmet and other PPE as deemed necessary.

Media blasting, also known as abrasive blasting, uses a variety of abrasive media beyond just sand. Common alternatives include aluminum oxide, glass beads, steel shot, garnet, and plastic beads. The choice of media depends on the application and the desired surface finish.

Media blasting can be used in a broader range of applications, from delicate cleaning and surface preparation to heavy-duty abrasive tasks. The ability to select from various media types allows for more flexibility. Media blasting, especially when using non-toxic or less hazardous media, is often considered a safer and more environmentally friendly alternative to sandblasting. It reduces the risk of health issues associated with silica dust exposure.

The main difference between sandblasting and media blasting lies in the type of abrasive media used. Sandblasting primarily used sand as an abrasive medium but has evolved to incorporate other media to address health and environmental concerns. Media blasting encompasses a wider range of abrasive media options, making it more versatile for various applications and often considered a safer and more environmentally friendly choice. The choice between the two methods depends on the specific requirements of the surface treatment or cleaning task at hand.

Wet Blasting vs. Dry Sandblasting

Is wet blasting better than sandblasting? Both wet blasting and dry sandblasting have their advantages and disadvantages, and the choice between the two methods should be based on factors like the type of substrate, the nature of the contaminants or coatings to be removed, environmental considerations, and safety concerns.

Wet blasting uses water to suppress dust, making it a cleaner and more environmentally friendly option compared to dry sandblasting. Wet blasting produces less heat, which can be advantageous when working with heat-sensitive materials. The water cushion can provide a gentler impact on surfaces, reducing the risk of surface damage. The presence of water can help inhibit the formation of new rust on exposed metal surfaces.

Dry sandblasting is often faster and more aggressive, making it suitable for heavy-duty applications. Dry sandblasting allows for the use of a wide range of abrasive media, providing versatility for various applications. Dry sandblasting does not generate wastewater, simplifying waste management. It does generate airborne dust, which can pose health and environmental concerns. Dust containment and extraction systems are required.

Wet blasting is often chosen when dust suppression, environmental concerns, and reduced surface damage are essential considerations. It’s suitable for certain applications like cleaning historical structures or removing coatings from sensitive surfaces. Dry sandblasting, on the other hand, is preferred for applications requiring more aggressive surface preparation and where dust containment and heat generation are not significant concerns.

PSI Levels in Different Sandblasting Applications

How many PSI does a sand blaster use? Pressure pot blasters and blast cabinets operate at varying PSI levels, often ranging from 80 to 100 PSI or higher. For industrial blasters, equipment can operate at very high PSI levels, often exceeding 100 PSI. It’s important to note that the choice of PSI is influenced by factors such as the type of abrasive media used, the hardness and thickness of the substrate, the desired surface finish, and the specific application requirements. Lower PSI levels may be used for delicate work, while higher PSI levels are employed for heavy-duty tasks. Proper training and safety precautions are essential when using sandblasting equipment, as the force and abrasiveness of the process can be dangerous if not controlled correctly.

If you have any questions about our blasting equipment and how it can help you, please contact us and we will be happy to help you.